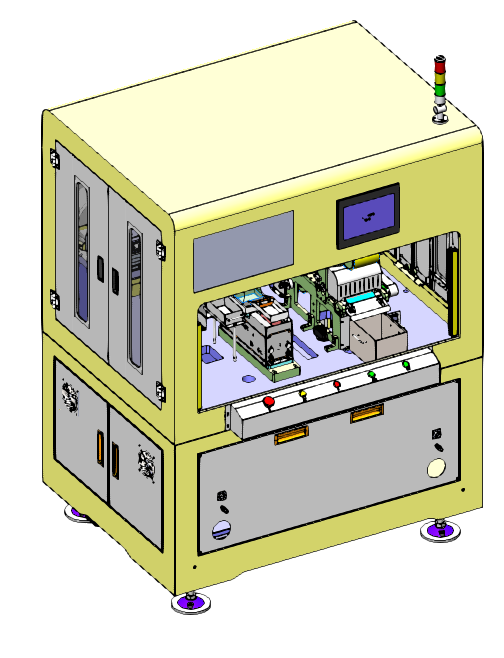

Full automatic material placement detection machine

Full automatic material placement detection machine

This equipment is mainly used for small product placement and appearance inspection.

Product advantages:

1. The vibrating plate is used for material separation, the CCD system is used for automatic screening and positioning, the manipulator is used for automatic material taking and discharging, and the PE film is automatically discharged and cut off.

2. Compact structure and small floor area.

3. Adopt linear motor to take and place products stably and quickly.

4. The mechanical action is controlled by PLC, the operation interface is simple and easy to understand, and the user password protection function is provided. PLC with touch screen can easily modify and save the preset motion control parameters of the machine.

Product specification:

Takt Time | 3600pcs/h | check the accuracy | ±0.2mm |

Number of reclaiming heads | 4 | Worktop height | 830±20mm |

Air supply | 0.5~0.7Mpa | Power supply specification | AC220V/50Hz/5Kw |

Suitable for product size | Max. 5 * 5mm | work environment | Class 1000 dust-free workshop |

Positioning mode | CCD定位 | Overall dimensions | L*W*H= 1400*1000*2000(mm) |