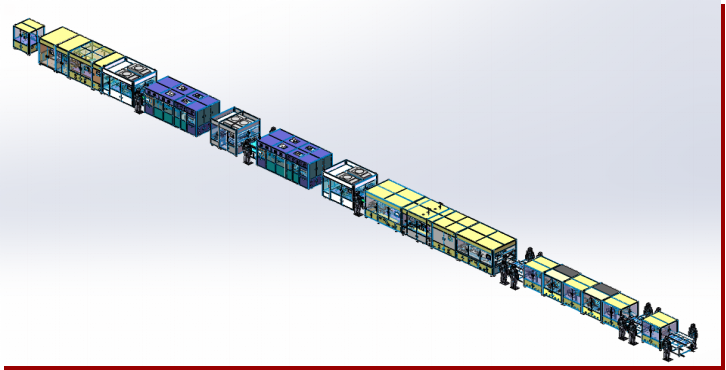

Fingerprint double gauge production line

Fingerprint double gauge production line

Fingerprint double gauge production line

(high temperature glue pasting machine, carrier plate PE film pasting machine, typesetter, plasma cleaner, DAF integrated machine, online defoamer, glue dispensing ring machine, hot plate machine, hot plate machine, spot welding machine, plate dismantling machine, electric testing machine, finished product film pasting machine, intelligent sorter)

Product advantages:

1. The whole line has a high degree of automation, and the refueling realizes non-stop operation. High off-line refueling safety.

2. Human machine cooperation shall be considered in the design of the whole line. In case of equipment failure or abnormal materials, the whole line shall be manually involved without shutdown.

3. The whole line equipment is equipped with shielding function, and can switch between film transfer mode and mounting mode.

4. The design of the whole line is modular, with high general performance and simple line replacement. It can quickly switch between different products and processes

5. For line equipment, Ethernet is used for communication. The equipment production information is displayed in a centralized manner, including equipment status information, material reminder, abnormal information report, etc. Realize the data docking provided by the future intelligent factory.

Product specification:

Whole line UPH | 1200pcs/h | Positioning mode | Auxiliary material bonding: upper and lower CCD alignment Pressure maintaining and testing: fixture positioning |

Repeated bonding accuracy of equipment | ±0.10mm | Camera pixels | 上CCD:600W 下CCD:600w |

Suction nozzle - pressure head | Quick detachable custom nozzle / indenter | Power supply specification | single-phase 220V/50hz.4KW |

Tape size | 6 inch inner diameter coil tape | Tray size | MAX: 300x120mm |